Formula and technology from Japan to produce back and seat, in our factory, we use all production lines imported from Japan, all machines are imported from Japan. The material of high density polyethylene is imported from Korea, Dainippon Ink (DIC Corporation) color concentrate, anti-ageing, fire retardant, moisture resistivity.

Seats with hyperboloid and the hollow surface layer structure, so this seat is very strong and safe to seat.

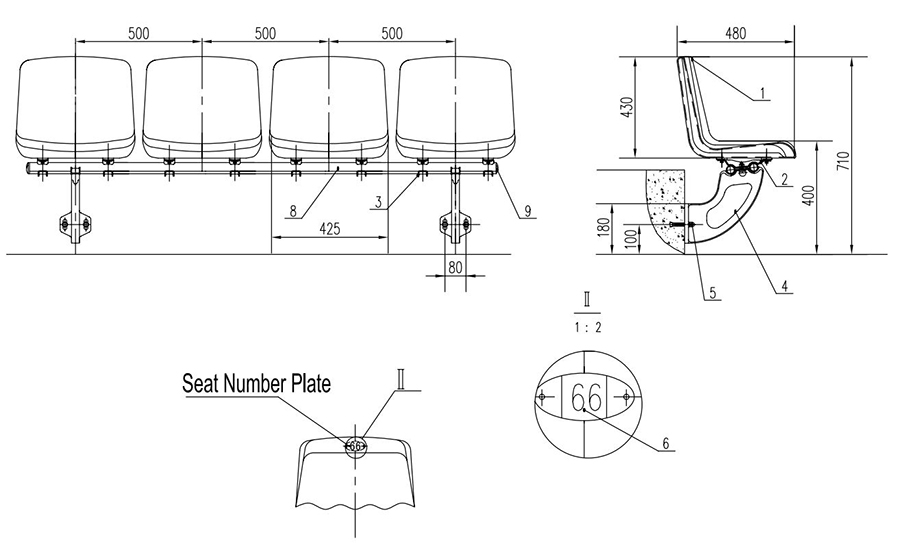

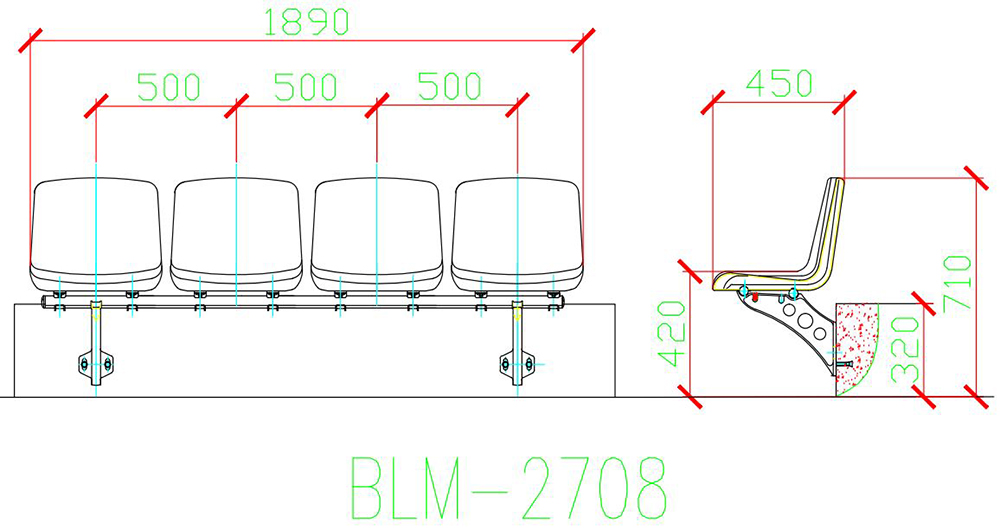

There are some hidden screw nuts at two side of chair so that metal parts will not take trouble to people.

We use expansion bolt to install the seat, drilling degree of unity in order not to break the waterproof layer of step.

- Material of plastic seat pan & backrest: High density polyethylene (Copolymer and homo polymer – PE).

- Accessories: Suitable accessories for fixing, like Screws/Bolts, Anchors, fasteners etc to be provided. All Accessories are galvanize treatment.

- Type: Fixed to floor directly by fasteners.

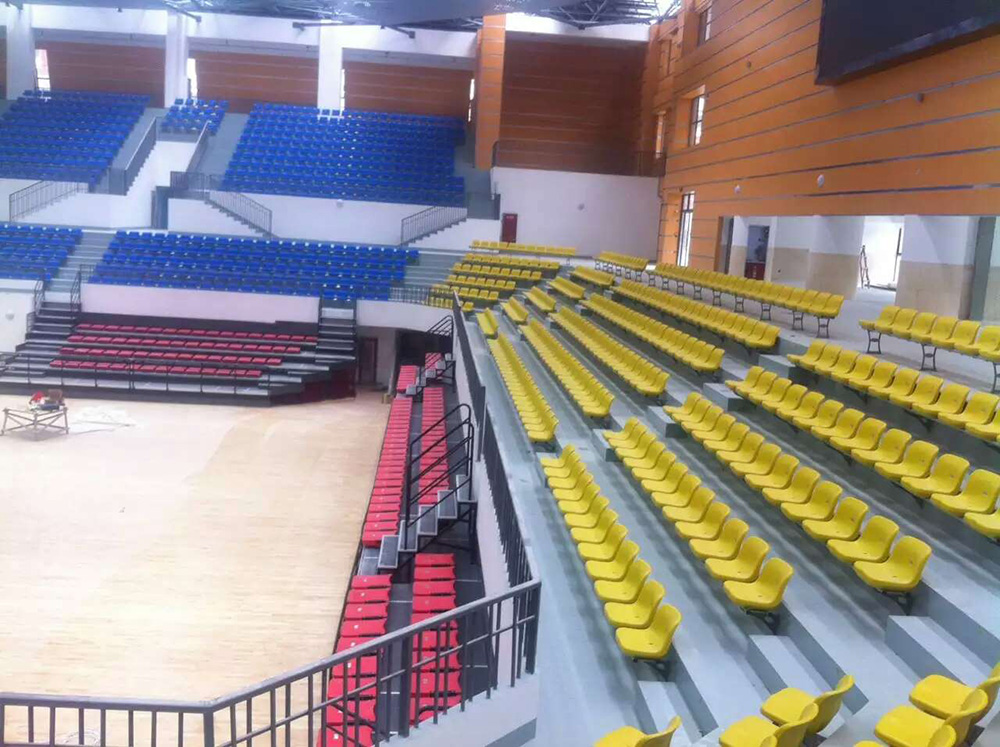

- Use: Outdoor/indoor stadium seats.

- Placing: Perfect seating to the concrete step without oscillation or shaking to any sides.

- Thickness of the seats at the rear edge is 8cm and decreasing to the front edge as you can.

Master batch with UV resistant additive. Mechanical durability. Material that allow deformation and elongation. Impact resistant (Not breakable by use). Weather resistance (rain, sun, mold, abrasion, color fading resistance.)