Telescopic Bleachers Technical Q&A

The telescopic bleacher is a public utility which can installed with seats. When it stretch out, it will form a ladder stand, when it draw back, it can be stored in a small space. Mainly used in multi-purpose room, stadiums, television studio, classrooms, multi-function use of indoor or outdoor hall.

Movable stand is made of following parts and system:

1. Contour platform (with casters)

2. Guardrail

3. Expansion drive(manual drive/power drive)

4. Front-mounted seat; rear-mounted seat(flip by hand or electric)

5. Control system

6. Other auxiliary devices(row of the display device, the obstacles stop device, limiting device)

The beams, columns of the telescopic bleachers using cold-formed steel; Other components like crosspiece, bottom wheel beam and railings are using high frequency welded pipe(well tube, rectangular tube, pipe, etc).

The material quality is “Q235A”, equal to old standard A3 steel. “Q”means Yield strength. “235” means the yield strength of the steel is 235MP, A level steel. Belong to ordinary carbon steels.

The wheels are made of iron that covered with polyurethane layer, diameter Ø100mm; named “4 inch thick double bearing polyurethane wheel”. Loading capacity is 250KG/each one. The polyurethane layer of the wheels have slight flexible when it under pressure.

The requirements of grandstand panel materials: divided into two type of indoor and outdoor. Usually, it depends on customer request. General indoor material is 18mm medium density melamine board. or 18mm composite board that covered with rubber leather or carpet; or 18mm composite board that covered with fireproofing board or fire prevention fillet. Although the melamine already have fire prevention composition, the multiply plywood still need to spray fire coatings.

Generally, the materials of step panel of outdoor stands are 2mm riffled plate or 18mm bamboo veneer.

If you choose the riffled plate as the step panel, you need to do periodic service(periodic anti-corrosion maintenance service); If you choose bamboo veneer as step panel, you need to cover it with rubber leather or carpet, but you can choose not.

The step edge of the stand is cladding with special production of striped of aluminum alloy article decoration. After the bronze surface oxidation process, the corner will sealed with plastic cover, looks not only beautiful but very safe.

Friction wheel drive device, the motor drives a high-strength shaft to rotate through the sprocket chain. The high-strength shaft drives multiple sets of friction wheels to rotate, and through the forward and reverse rotation of the motor, the stands are driven to extend and retract. Since this device is installed under the steps in the front row (that is, the first row) of the stands, it is called the front drive type.

In generally, the electric control system of movable stand will adopt trip switch, AC contactor, the pros and cons of the switch button(manual control box,infrared remote control, a touch screen) mode. The system using limit position stop mode, it means when you press the button, the stand will keep running to the limited position, then stop. For half-way stop, you must press the stop button. The system is equipped with a thermal relay, have reload protection of itself.

Besides, according to the customer request, can add P sound device, digital row number display device etc.

1. When the steel structure is shaped up, after the surface polished, surface degreasing, rust clean, spray anti-rust paint once and finish twice, the surface color is greenish-blue and black, or the customer specified(optional) color.

2. Spraying plastic.

Under the front-drive mode, the seats are installed in the grandstand step forefront, both the height of step and seat panel form the angle of seating height. The modality is fixed seat panel and folding backerest. So if the steps are too low and double seats situation are not supporting the backrest folding seats. Backrest folding seat only can be controlled by manual, and only can be installed on each layer as a single row seats system.

Riser-mounted seats are installed behind the grandstand steps. They are single-seat foldable, row-turned seats. The lower part is equipped with a flip device box seat, and the box seat is equipped with a tension spring to offset most of the weight of the seat. The resistance torque reduces the power of flipping the seat. The number of rear-mounted seat row overturns is generally 6-12 seats in a row. The rear-mounted seat can be flipped electrically, but the premise is that the seat plate and backrest of the seat can be automatically folded under the action of gravity or torsion spring. The number of seats that can be turned by each motor is similar to the number of seats that can be turned manually, 6-12 seats. Regardless of the form of the stands, rear-mounted seats can be installed as long as the floor height is appropriate.

According to the different type of seats they equipped, it is between 240mm to 320mm.

When installing the telescopic stand, demand ground is a plane, the flatness error must not be more than 8mm/10m² installation area can not have bumps, the ground should not be to smooth, it is better not to installed the stand on the ground which covered with plastic mulch.

If you are going to put the stand on the floor directly, we request the material of the floor must be very compact wood, like beech or xylosma etc; If the floor is supported by wooden keel, you should adopt strengthen measures at the areas which the wheels will passed. If the stand is placed in the floor surface, then the floor need have enough loading capacity.

Basically has the following points:

1. Loading capacity of stand panel: 300kg/m².

2. Storey height: 240-320mm based on seat type and customer request.

3. Width of foot step: 750-1000mm based on seat type and customer request.

4. Stand operation speed: 5m/min.

5. Power: 380V or 220V, depends on the actual situation.

6. Motor power: According to the actual situation.

The side rails of the stands are:

1. Detachable type — Use when the stand is placed under the cantilever or when the side of the stand is not 90° from the front.

2. Detachable railings — Use when the stand is placed under a cantilever or when the side of the stand is not 90° from the front.

3. Disassembly-free type — It is used neatly on the side of the stand and 90° from the front.

4. The materials are made of round pipes of Ø38×1.2, or stainless steel pipes; or rectangular pipes and wooden boards.

5. Folding railings.

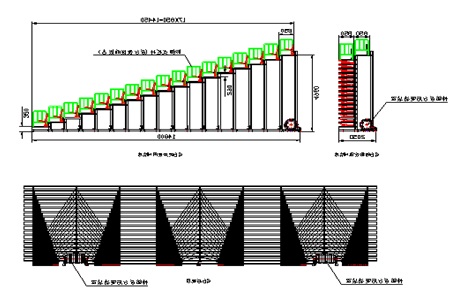

Attached picture: Several forms of making the side railings of the grandstand

1. Rectangle (the most common form)

2. Rhombus (the more common form)

3. Trapezoid

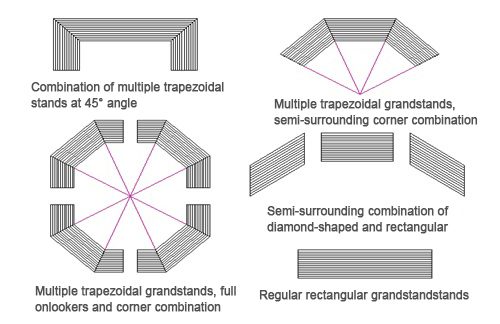

Attached picture: Plane combination of several stands

1. Site installation range(length, width, height).

2. Architectural setting of installed range of field, like doors, windows, girders, pillars, balconies, steps etc. Need indication correct position and size.

3. Other facility of installed range of field.

Such as heating installation, air-conditioning, lighting equipment(is there any droplight) etc. Indication correct position and size, at same time, should clear whether the equipments can be moved in the specified space. It will be considering as a whole processing of the design.

4. Ensure the decorate status of installation range of field.

Including placement and packaging of heating installation, air conditioning etc.

The decorate covers an area of doors, windows, girders, pillars. The space of the droplight.

Floor area of installation area of field:

Including ground processing form, completion date, loading capacity etc.

5. Installation area of field and other construction conditions:

Completion date which including decorate and other construction parts. General requirements, at the period of installation and examination, to avoid damage and slowdown, does not allow any other constructors doing construction in the same field. Except in exceptional circumstances.

6. Provide simple drawing. The drawing should including all the necessary information.