Seat dimensions:

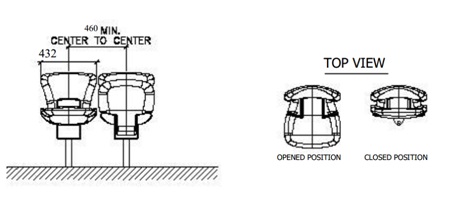

Width: 460 ± 5mm

Depth: 460 ± 5mm

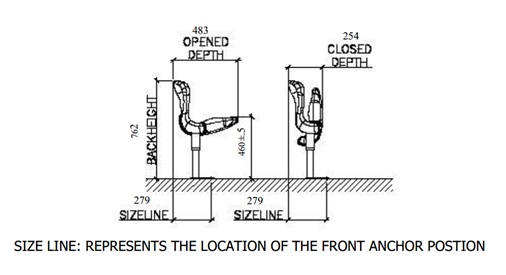

Chair backrest height: 440 ± 5mm

Seat material description:

Seat material: High-density polyethylene

Seat support: Metal stamping

Seat bracket: Pressure casting aluminum alloy

Options:

Seat number

Customized colors

Seat description:

1. The seat is a split hollow plastic flap chair, and the chair surface material is made of high-density polyethylene (HDPE), which is processed by the international advanced hollow blow molding manufacturing process at one time. It has rounded corners on the seat surface, aging resistance, high and low temperature resistance (+80°C to -60°C), non-toxic, excellent chemical stability, and good impact resistance.

The comprehensive performance complies with the QB/T 2601-2003 “Sports Stadium Public Seating” standard, and the overall service life is ≥15 years.

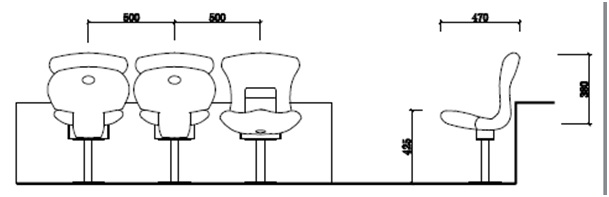

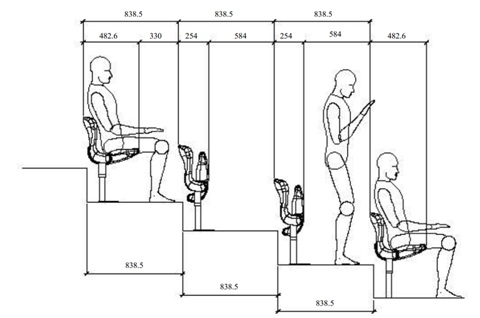

2. Seat surface dimensions: Seat width × seat depth × seat back height = 460 × 460 × 440(mm), the thinnest part of the seat is not less than 3mm, the installation distance is 500mm, and the height of the seat surface from the ground is 430mm.

3. Seat bracket: High-quality steel pipe with a material of ¢28mm and a thickness of 2mm is bent and formed, with beautiful appearance, compact structure, high strength, impact resistance and non-corrosion. All steel components are pickled and phosphated before being electrostatically sprayed to enhance corrosion resistance.

4. The seat plate is turned over and rests on the weight of the seat cushion, so it can be automatically stowed without a spring device.

5. Installation method: suspended single installation, the bracket is connected to the side of the concrete step by M10mm×80mm expansion bolts, and the connection is firm and not loose. The seat installation channels are aligned and have the same height without significant drop.

Accessories:

Bracket: It adopts precision aluminum pressure casting suspension bracket with polished surface and plastic spraying (the same color as the seat). It has the characteristics of beautiful appearance, dense structure, high strength, impact resistance and non-corrosion.

Connecting the round pipe: The outer diameter is Φ32mm thick galvanized pipe, and the end of the round pipe is sealed with a rubber plug.

All steel components: After silane treatment, the surface is oxidized and galvanized to enhance its corrosion resistance.

Fasteners: The seat, connecting plate and bracket are connected with Jinyi screws and cushioned soft pads. The bracket is connected with the side of the stand step by expansion bolts, and the connection is firm and not loose.

Aluminum seat number and row number setting: The seat number is set on the backrest, embedded design; the row number is set on the side of the seat on both sides of the aisle, using the same plastic row number seat as the seat, embedded installation .

Seat features:

The seat surface adopts Japanese formula and technology, and is produced by all Japanese imported production lines, South Korea imported high-density polyethylene material, and Dainippon Ink (DIC) color masterbatch, which has good performance in anti-aging, flame retardancy and water repellency. The seat surface adopts a hyperboloid and hollow double-layer structure, which greatly improves the strength of the seat and meets the safety of use in public places.

When designing the seat, the parting surface is considered on both sides of the seat surface, and the pre-embedded nuts are on the back and side of the seat surface to avoid accidental injury to people. The curve is naturally smooth and smooth, the surface is smooth and smooth, and the overall feel is pleasing to the eye.

The suspension bracket is made of aluminum alloy, and the surface is polished and the electrostatic spraying process is used to ensure the surface quality, corrosion resistance and strength of the product to the utmost extent.

The bracket is installed with special expansion bolts, and the perforation is uniform to ensure that the waterproof layer of the steps is not damaged, so as to ensure the installation strength and prevent water leakage from the steps.