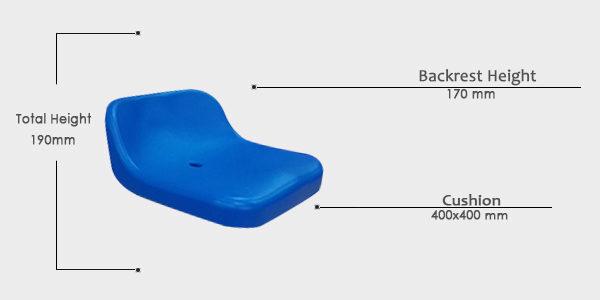

High-density polyethylene(HDPE) material on plastic, blow molding seat. The new plastic materials, thickness is 7.5 mm, resistant to the high temperature and water.

Japan blow molding seat equipment, the equipment is controled by full-automatic computer, and don’t absorb any recycling material to produce stadium seats, so our material is full new raw materials. We adopt Japan technical process, and the producing equipment is imported from Japan. So that we can ensure high quality, durability, anti-fading and with ultraviolet inhibitors for our stadium seats.

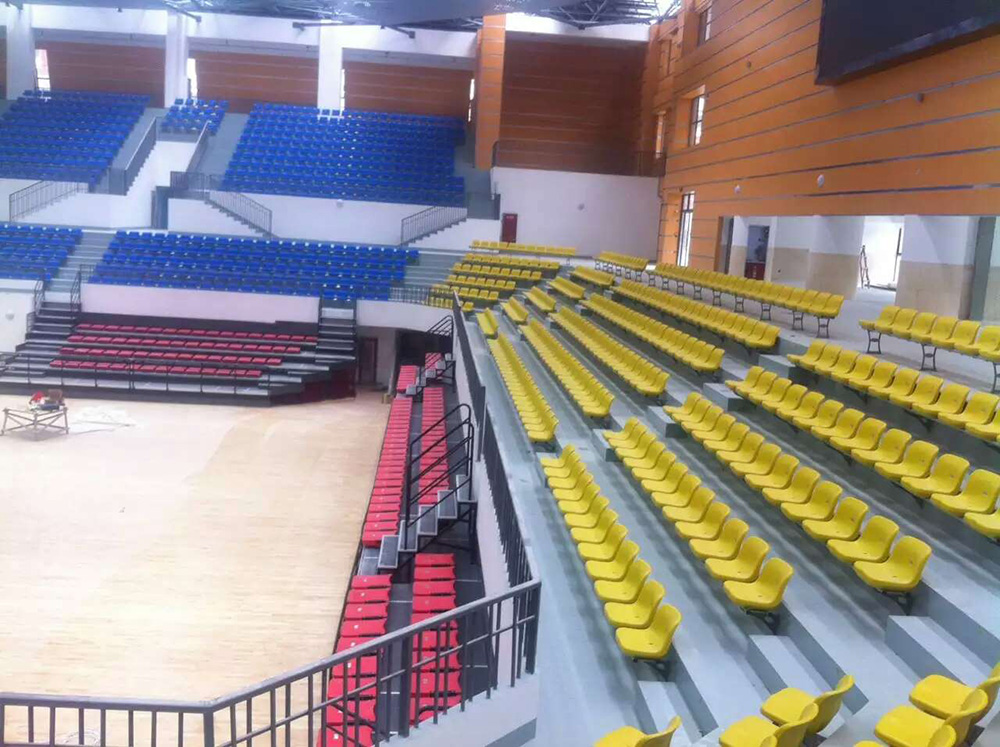

- Blow seat BLM-2508 the introduction of Japanese design a glider factory dedicated seat stadium has been equipped with many medium and large venues, with favorable results.

- Seat ergonomic chair line, smooth curve over the natural, smooth, smooth, ride comfort, the overall installation effect is beautiful.

- Chair side material: High-density polyethylene, produced by the Japanese DIC masterbatch, use the advanced Japanese blow molding process, the whole production line imported from Japan (1998, Japan imported complete from blow seat production line equipment, technical data) to ensure stable and reliable product quality, resistance to aging, weathering resistance, life protection have been great.

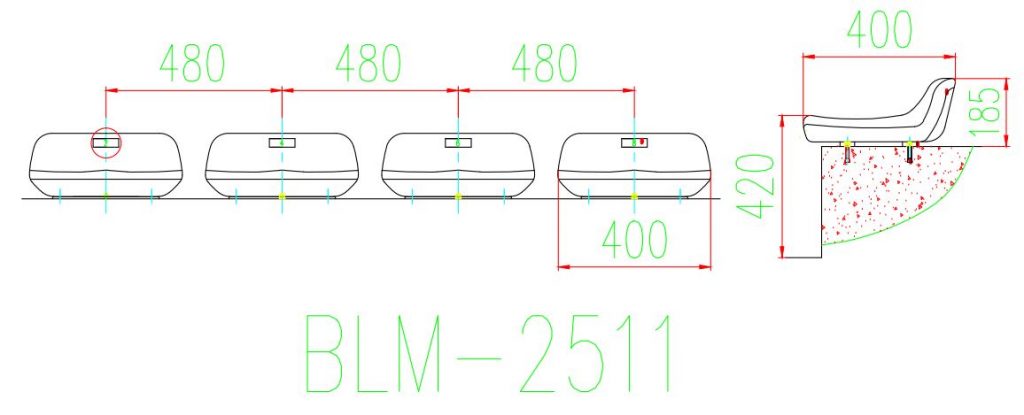

- Installation and support: The seat supporting metal stamping parts, the product surface quality and corrosion resistance have been the maximum guarantee.

- Left end surface of each seat block arranging the installation location, block arranging riveted aluminum alloy plate, solid and reliable.