Model: JY-606M

Function:

- Conference and theatre exclusive seating, steel and wood structure, middling height backrest.

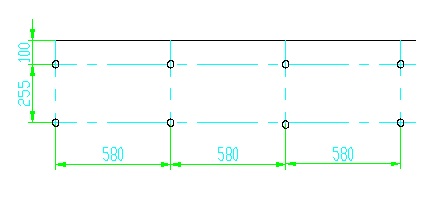

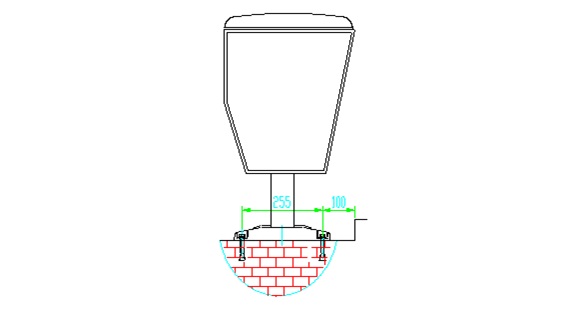

- Two legs, it can be fixed or removed.

- It can configured number plate and caparmcaps.

Material specification:

Backboard: High quality multiply plywood, burst size of carbine reach china national stands.

Seatboard: High quality multiply plywood, paired with an internal layer of sound-absorbing foam, acoustical seat pans enrich the sound and augment the andience’s listening pleasure.

Foam of cushion: High rebound stereotypes of cold foam sponge, the density of foam reach 35-50kg/m³.

Fabrics: Hemp soft cloth, flame retardancy, abrasion resistant, resistance to soiling, antistatic, resistanc to fading, resistanc to transmutation and comfortable.

Rebound structure: Damping design, reset exactly, low noise, noise level: ≤20 decibel.

Arm frame: Q235 steel welded molding, pickling treatment by electrostatic spray forming.

Arm: Beechwood arm, the arm surface is very smooth, feel comfortable.

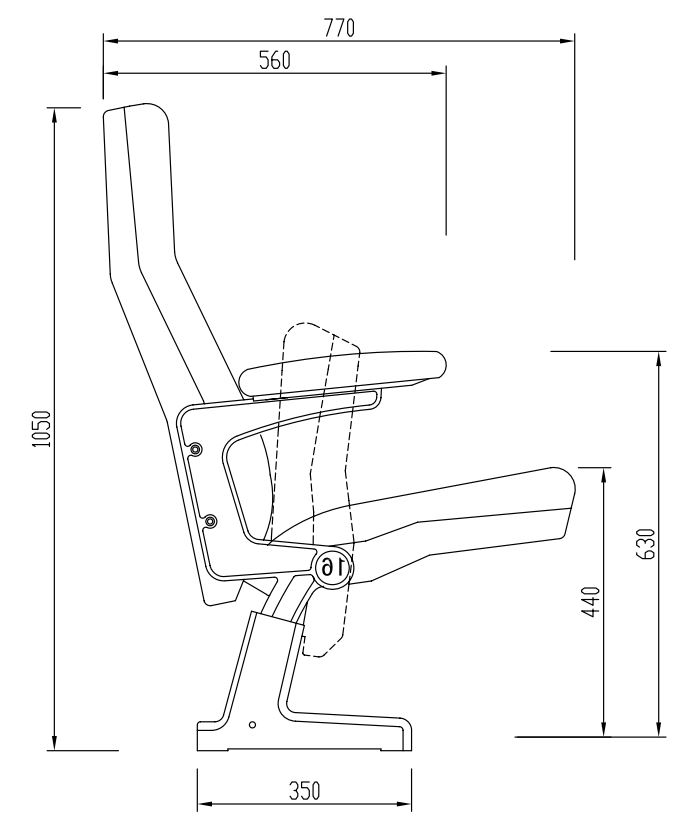

Main Technical Parameter:

| Height of chair | 105cm | Center to center distance | 55cm |

| Height of seat board | 44cm | Row distance | ≥ 90cm |

| Height of armrest | 63cm | Least of length | 42cm |

| Width front and back | 77cm | Density of foam | 45kg/m3 |

| Length of cushion | 48cm | Max supporting height | 150kg |

| Width | 55cm | Least times of reversal | ≥150000times |

Chair construction:

The chair is made of armrest(steel frame, supporting leg, armrest panel), backrest, seat(fabric, steel skeleton, polyurethane)and the connection reversal construction.

Character:

1. Soft back cushion adopts “3-in-1” technology which closely integrates cloth, foam polyurethane, metal construction into a whole. It appears to be more durable.

2. Seat board is multi-layer veneer, a mat hull adoption absorbs the sound pore specially, having to absorb the sound function perfectly.

3. Backboard uses high-quality multi-layer veneer.

4. We apply torsional double-spring buffer bouncing design for turning over seat cushion. It has the accurate reset and low noise.

5. Plywood armrest panel is more durable.

6. Brackets utilize superior aluminium alloy for die-casting and surface polish with smooth and pleasing appearance.